Transformers are passive electrical devices that transfer electrical power between two circuits to increase or decrease the voltage the electricity so it will be best-suited to the final application or end device. Transformers accomplish this through magnetic induction between coils.

Transformers can be very small or very large depending on the application requirements, ranging in physical size from less than a cubic centimeter to hundreds of tons. Some transformers are specially developed to regulate electricity in applications that require very high voltages for operation.

How High Voltage Transformers Work

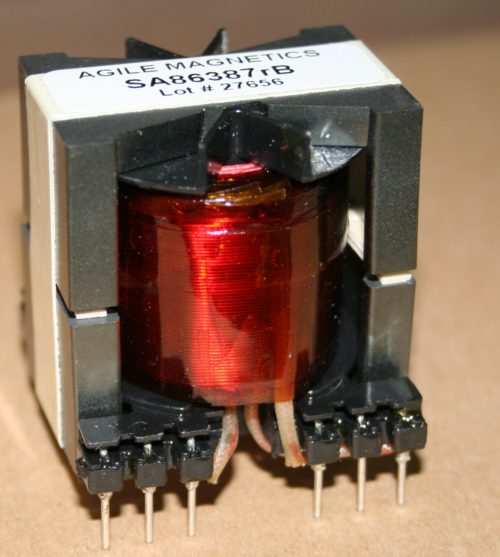

A high voltage transformer typically has two coils, each wrapped or wound around varying types of core material. The primary coil will be connected to the input current, which must be alternating current (AC). Connecting a direct current (DC) flow to the primary coil won’t generate any current in the secondary coil.

As the AC current passes through the primary coil, it produces a changing magnetic field that induces alternating voltage in the secondary coil and alternating current in the circuit connected to the secondary coil. This process is called induction, because the two coils don’t actually make contact.

In order to increase or decrease the voltage or phase configuration coming out of the secondary coil, the number of turns in the secondary coil must be adjusted relative to the primary coil. A step-up transformer increases voltage by adding more turns on the secondary coil than the primary coil. Conversely, a step-down transformer decreases voltage by having fewer turns on the secondary coil than the primary coil.

How High Voltage Transformers are Used

Our high voltage transformers are used for a wide range of different applications that require a transformer than can handle 15,000 volts safely and accurately. The following industries frequently use high voltage transformers:

- Automotive

- Aerospace

- Renewable energy

- Waste disposal/clean-up

- Manufacturing

- Distribution

- Scientific/engineering testing and research

High voltage transformers see usage in very common applications, such as hybrid vehicles and braking systems, to less common applications such as CNC machine tools, windmills, lasers, and plasma generation.

Choosing the Right High Voltage Transformer

Making sure you choose the right high voltage transformers for your projects is essential. One of the first parameters that must be accurately defined is the frequency of the primary input voltage coming into the transformer. Common frequencies include 50 Hz, 60 Hz, 400 Hz and higher. Most European power is 50 Hz, while North American power is most often 60 Hz. By comparison, aerospace applications often reach the 400 Hz level.

At Agile Magnetics, our high voltage transformers can cover a wide range of applications. Our standalone transformers can be built for output voltages up to 15KV. For applications that need an even higher output, oil immersion transformers with output voltages up to 30KV are also available.

Agile Magnetics can custom-build incredibly reliable high voltage transformers to match any intended application from delicate instrumentation to heavy-duty military or aerospace usage. Our standards include void-free potting to avoid corona and include high dielectric materials. Our high voltage transformers come in three styles:

- 50/60Hz Layer Wound transformers are constructed with a silicon steel core and rely on layer insulation and margins on each layer of windings to achieve isolation from high voltage. These transformers can also be immersed in dielectric oil by the customer for added isolation when needed.

- High Frequency Layer Wound transformers utilize a ferrite core and are much smaller than 50/60Hz models. They are most often encapsulated using state-of-the-art potting equipment and may be immersed in dielectric oil.

- Universal Wound transformers wind the high voltage secondary coil using a universal winding technique to allow for additional space between the turns, thereby allowing for more distance between turns with high voltage potential.

However complex or specialized your needs may be, our team of experts can help you find the right transformer for the job. If a standard transformer won’t work, we’re happy to customize one for you. Our innovative custom designs and premium materials result in high voltage transformers that perform with unparalleled reliability.

Contact us today to find out how Agile Magnetics can provide the high voltage transformers you need.

Comments are closed